Rope end fittings

APAG

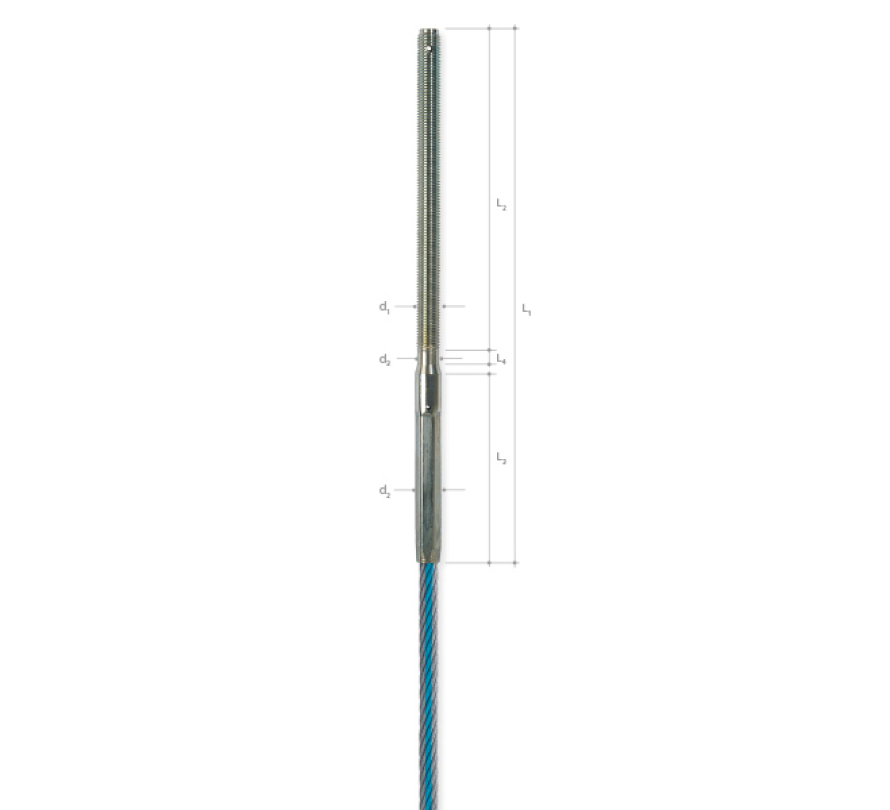

Threaded Swaged Sockets

Product Data

- APAG-end connections are TÜV testedand approved according to TRA/EN81.

- APAG-end connections transmits 80% of minimal breaking load of traction rope.

Advantages

- simple, fast and safe end terminations

- shortened installation time, since no mounting of end connections by customers

- no special tools required

- the compact type enables a very tight arrangement of ropes and parallel running ropes

- simple securing against rotation

- check hole for rope end position

- quiet operation because there areno individual parts

APAG (CTP®)

Threaded Swaged Sockets

Product Data

- APAG-end connections are TÜV tested andapproved according to EN81.

- APAG-end connections transmits 80% of minimal breaking load of traction rope

Advantages

- simple, fast and safe end terminations

- shortened installation time, since no mounting of end connections by customers

- no special tools required

- the compact type enables a very tight arrangement of ropes and parallel running ropes

- simple securing against rotation

- check hole for rope end position

- quiet operation because there are no individual parts

Eyelet bolt

with thimble

Product Data

- eyelet bolt steel St 37, zinc-plated

Advantages

- simple, fast and safe end terminations

- no special tools required

- simple securing against twisting

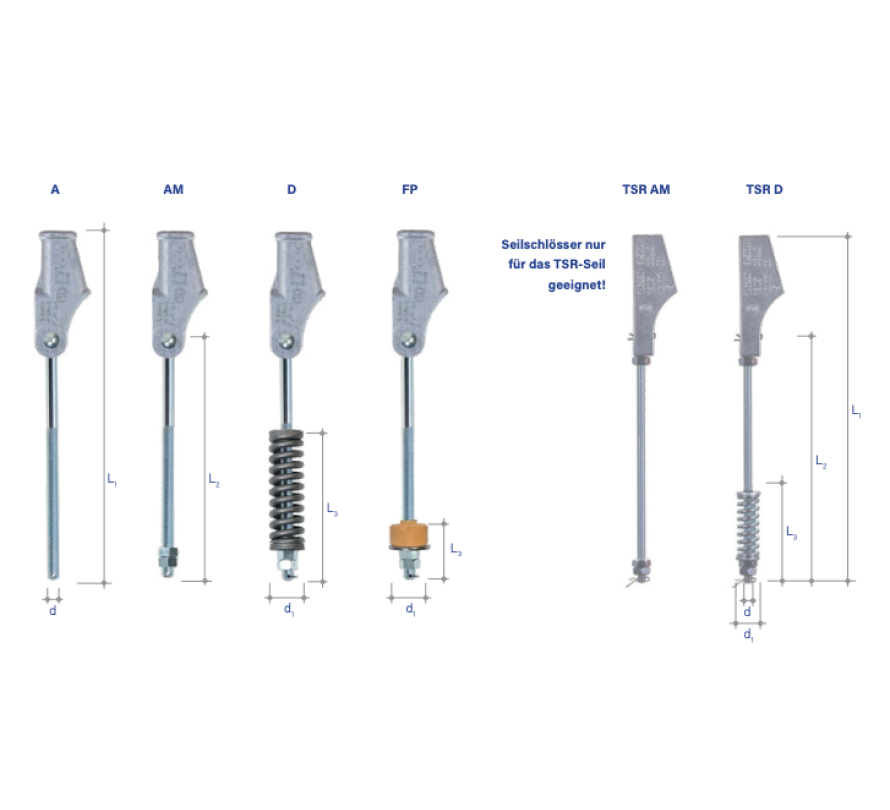

Wedge Socket (CTP®) Asymmetrica

Wedge Socket

- Cast rope lock, galvanized steel

- incl. wedge, pre-assembled safety splints

- Rope lock transfers 80% of the minimum break force of the rope

- Threaded rod, galvanized steel

- The assembly and operation is subject to the requirements in Annex C of the EN 13411-6 standard

Advantages

- can be assembled safely and simply on-site

- Can only be used with springs, buffers are not allowed for use with CTP ropes

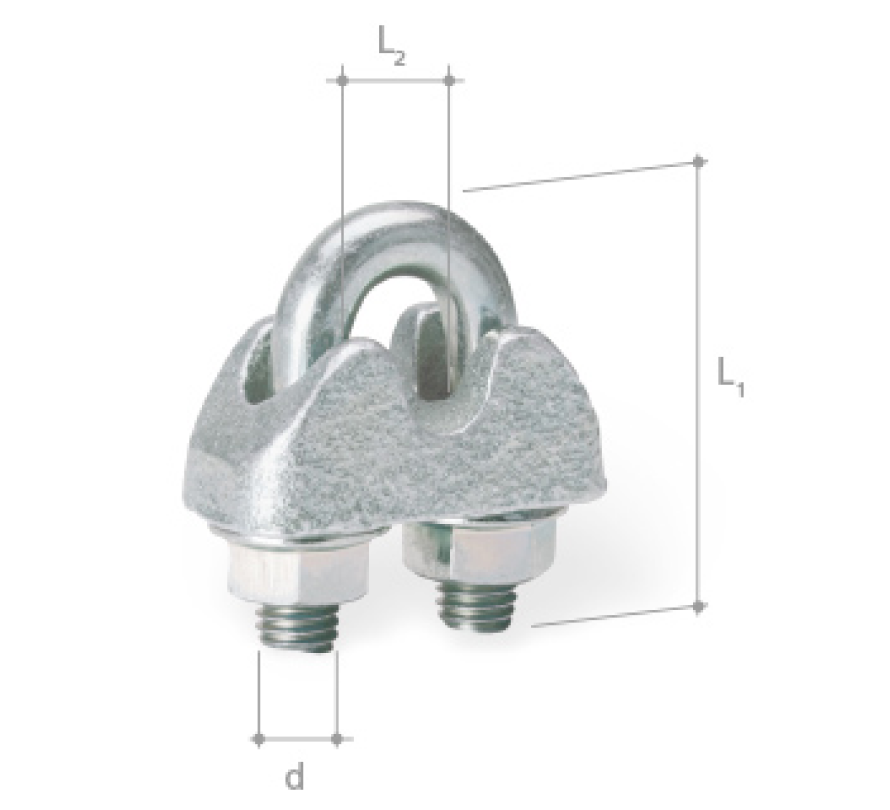

Rope Clamp

(EN 13411-5)

Product Data

- Rope Clamp

- zinc coated

- for mounting and operation the explanations of the norm EN13411-5 are valid

Advantages

- can be assembled safely and simply on-site